What I Did

After conducting the research below I ended up using the Rigid Insulation option #2:

- Lifted floor boards

- Inspected all joists and subfloor space, cleared air bricks, removed debris

- Cut old floorboards into 1” strips on table-saw to make battens (recycling!)

- Several central heating pipes were hanging loose, so I made some simple plywood brackets to hold them firmly

- Fit pipe insulation (Screwfix 72357) to all central heating pipes

- Reworked some of the mains cables to add additional double sockets whilst access was easy

- Made a simple depth tool and pinned battens 75mm below top of joists with Paslode cordless nail gun (Screwfix 44P3X)

- Cut tight-fitting Celotex GA4075 insulation between joists, pushed down to rest on battens

- Used 100mm wide aluminium foil tape (Toolstation 53122) to seal between insulation panels, and around boundaries

- Fitted 18mm P5 flooring-grade chipboard (BMD) as new floor, with Screwfix 49231 floorboard screws

Research

Underfloor insulation of suspended wooden floors can save ~£150-£200 per year on heating costs. Needs to be done properly to ensure do not cause damp / wood rot. General guide:

- Lift floor boards

- Initial checks:

- Remove any debris

- No damaged joists / rot / unstable pillars

- Ensure all air bricks are clear, and sleeper walls ok

- Check all pipework is insulated

- Ensure electrical cables will be outside the insulation (do not want overheating)

- Fit insulation, a couple of choices:

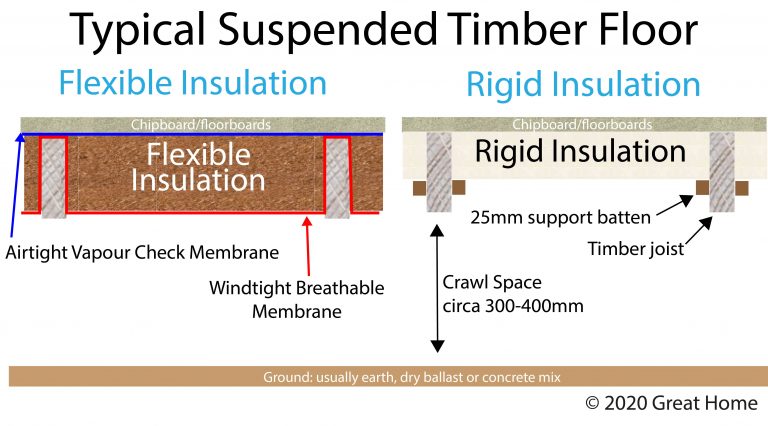

![]()

- Option 1: sheep’s wool / fibre insulation

- Looks like this needs more effort, and double the thickness to get same insulation level

- Lay breathable airtight membrane over joists, forming wells for the insulation between the joists, as per image below… stops wind washing and allows any residual vapour to escape

- Install high density (to avoid settlement over time) natural hygroscopic insulation product such as sheep’s wool (but it will need to be treated to prevent moths and other insects eating it), wood fibre or Jute insulation (made from recycled cocoa and coffee bean bags) as these will regulate the water vapour by absorbing it when necessary and releasing is again slowly once humidity levels reduce

- Lay vapour control layer on top of the underfloor insulation (this slows the passage of water vapour through to the insulation but does not stop it like a vapour barrier would). All the time ensuring the correct overlaps and the correct taping of all edges Including the joint between the floor and the walls

- Option 2: PIR thermal insulation board,e.g. Celotex GA4000 series

- Needs accurate cutting to get good seal, but as it is faced with aluminium on both sides does not need additional vapour layers. Has highest insulation rating, typically 0.022 W/mK

- Fit continuous 25×25 battens to sides of joists 75mm below tops, helps airtight seal

- Cut boards to size and fit

- Fill any gaps with expanding urethane foam

- Use aluminium 100mm tape to seal across joists and joins between boards (double wide over joists to get good overlap)

- Option 1: sheep’s wool / fibre insulation

- Re-lay flooring

References / Resources

- Google “how insulate suspended floor”

- Article re Underfloor Insulation of Suspended Timber Floor

- UK YouTube video showing second technique

- Airtight Suspended Timber Floors (Dupont)

- Adding Underfloor Insulation to Existing and Older Properties (Eco Home Essentials)

- How to Make Your Floors Warmer